- "Savaitės pasiūlymas"

- "AKCIJOS"

- "Bosch akcija"

- "Karcher akcija"

- "Metabo akcija"

- "Sodo ekspertai.lt pasiūlymai"

- Apšvietimas

- Automobilių prekės

-

Elektriniai įrankiai

-

Akumuliatoriniai įrankiai

- Akumuliatorinės frezos

- Akumuliatorinės išilginio pjovimo staklės

- Akumuliatorinės mūro frezos

- Akumuliatorinės patikros kameros

- Akumuliatorinės skardos žirklės

- Akumuliatorinės viniakalės / kabiakalės

- Akumuliatoriniai daugiafunkciniai įrankiai

- Akumuliatoriniai diskiniai pjūklai

- Akumuliatoriniai fenai

- Akumuliatoriniai gręžtuvai-suktuvai

- Akumuliatoriniai juostiniai pjūklai

- Akumuliatoriniai kampiniai šlifuokliai

- Akumuliatoriniai maišytuvai

- Akumuliatoriniai obliai

- Akumuliatoriniai perforatoriai

- Akumuliatoriniai pjūklai metalui

- Akumuliatoriniai poliruokliai

- Akumuliatoriniai prožektoriai

- Akumuliatoriniai siaurapjūkliai

- Akumuliatoriniai skersavimo pjūklai

- Akumuliatoriniai šlifuokliai

- Akumuliatoriniai smūginiai gręžtuvai/suktuvai

- Akumuliatoriniai smūginiai veržliasukiai

- Akumuliatoriniai suktuvai

- Akumuliatoriniai tiesiniai pjūklai

- Akumuliatoriniai tiesiniai šlifuokliai

- Akumuliatorinių įrankių rinkiniai

- Kiti akumuliatoriniai įrankiai

- Daugiafunkciniai įrankiai

- Dažų pulverizatoriai

- Dulkių nutraukimo įranga

- Galandimo - šlifavimo staklės

-

Gręžimo, tvirtinimo įrankiai

- Atskėlimo plaktukai SDS-max

- Atskėlimo plaktukai SDS-plus

- Deimantinio gręžimo mašinos

- Elektriniai kabamušiai

- Gręžimo staklės

- Gręžtuvai

- Kampiniai gręžtuvai

- Maišytuvai

- Metalo frezavimo staklės

- Perforatoriai SDS-max

- Perforatoriai SDS-plus

- Smūginiai gręžtuvai

- Smūginiai suktuvai

- Smūginiai veržliasūkiai

- Suktuvai

- Klijavimo, kaitinimo įrankiai

- Kroviklis - radijas

-

Medžio apdirbimo įrankiai - staklės

- Briaunų laminavimo staklės

- Frezeriai

- Lankstų gręžimo - įstatymo staklės

- Leistuvinės obliavimo staklės

- Medienos tekinimo staklės

- Medžio frezavimo staklės

- Medžio obliavimo-reismusavimo staklės

- Medžio šlifavimo staklės

- Obliai

- Parketo šlifavimo staklės

- Pjovimo - frezavimo staklės

- Rankinės sujungimų frezavimo staklės

- Reismusavimo staklės

- Siaurapjūklinės staklės

- Universalios daugiafunkcinės staklės

-

Pjovimo įrankiai

- Betono / akmens pjovikliai

- Diskiniai medžio pjūklai

- Diskiniai metalo pjūklai

- Formatinės pjovimo staklės

- Juostiniai pjūklai

- Metalo kirpimo įrankiai

- Mūro frezos

- Plytelių pjovimo staklės

- Putoplasto pjūklai

- Siaurapjūkliai

- Skersinio pjovimo staklės

- Stacionarūs diskiniai pjūklai

- Tandeminiai pjūklai

- Universalūs pjūklai

- Šlifavimo/pjovimo/tekinimo įrankiai

-

Akumuliatoriniai įrankiai

- Generatoriai

- Gervės. Diržai.

-

Įrankių priedai

- Adapteriai/patronai

-

Akumuliatoriai įrankiams

- Black+Decker Akumuliatoriai

- Bosch akumuliatoriai

- Cramer akumuliatoriai

- Cub Cadet

- DCK

- Dewalt akumuliatoriai

- Dremel akumuliatoriai

- Echo akumuliatoriai

- EGO Power+ akumuliatoriai

- Flex akumuliatoriai

- Hitachi akumuliatoriai

- Ikra mogatec akumuliatoriai

- Makita akumuliatoriai

- Metabo akumuliatoriai

- Milwaukee akumuliatoriai

- Scheppach akumuliatoriai

- Worcraft akumuliatoriai

- Worx akumuliatoriai

- Akumuliatorių krovikliai

- Daugiafunkcinių įrankių priedai

- Diskai

-

DREMEL įrankių priedai

- Abrazyviniai antgaliai

- Aliuminio oksido šlifavimo akmenys

- Deimantiniai antgaliai

- Didelio našumo abrazyviniai šepečiai

- Dremel priedų komplektai

- Frezos (HSS)

- Graviravimo antgaliai

- Grąžtai stiklui

- Greitaeigiai pjaunamieji antgaliai

- Guminiai poliravimo antgaliai

- Impregnuoti poliravimo ritinėliai

- Koteliai

- Nerūdijančio plieno šepečiai

- Plieninės vielos šepečiai

- Poliravimo diskai

- Šerių šepečiai

- Silicio karbido šlifavimo akmenys

- Šlifavimo akmenys grandinei galąsti

- Suspaudžiamosios įvorės

- Universalūs griebtuvai

- Volframo karbido pjaunamieji antgaliai

- Žalvariniai šepečiai

- Dremel valdymo priedėliai

- Dulkių nusiurbimo sistemos

- Frezos

- Grąžtai / kaltai

- Gręžimo karūnos

- Gręžimo stovai

- Kniedės

- Kreipiančiosios liniuotės

- Maišytuvai

- Obliavimo peiliai

- Pjovimo juostos

- Pjūkleliai tiesiniam pjūklui

- Prailgintuvai

- Priedai medžio tekinimo staklems

- Siaurapjūkliai pjūkleliai

- Šlifavimo juostos

- Stovai įrankiams

- Suktuvo antgaliai

- Tekinimo peiliai

- Tepalai įrankiams

- Universalūs priedai

- Vieliniai šepečiai

- Vinys / kabės

- Kopėčios

- Laisvalaikio prekės

-

Matavimo įrankiai

- Betono kietumo matuokliai

- Daugiafunkciniai testeriai, multimetrai

- Dažų storio matuokliai

- Drėgmės ir temperatūros matuokliai

- Garso lygio matuokliai

- Gulsčiukai

- Ieškikliai

- Imtuvai

- Lazeriniai atstumų matuokliai

- Lazeriniai rotaciniai nivelyrai

- Linijiniai lazeriai

- Matavimo įrankių priedai

- Mikrometrai

- Optiniai nivelyrai

- Posvyrių/kampų matuokliai

- Ratukinės atstumo matuoklės

- Ruletės

- Slankmačiai

- Taškiniai lazeriai

- Temperatūros matuokliai ir kameros

- MOTO prekės

- Oro sausintuvai

-

Pneumatinė įranga

- Filtrai

- Kompresoriai betepaliniai

- Kompresoriai stūmokliniai

- Kompresorinė alyva

- Kompresorių cilindrai

- Oro kompresorių atsarginės dalys

-

Pneumatiniai įrankiai

- Aerografai

- Gręžtuvai, suktuvai

- Jungtys

- Kiti pneumatiniai įrankiai

- Pneumatinės skardos kirpimo žirklės

- Pneumatiniai - dujiniai vinių ir sąsagėlių kalimo prietaisai

- Pneumatiniai adatiniai kaltai

- Pneumatiniai daugiafunkciniai įrankiai

- Pneumatiniai kaltai

- Pneumatiniai kampiniai šlifuokliai

- Pneumatiniai kniedikliai

- Pneumatiniai pistoletai tepalui

- Pneumatiniai siaurapjūkliai

- Pneumatiniai šlifuokliai - poliruokliai

- Pneumatiniai stiklo pjovikliai

- Pneumatiniai tiesiniai šlifuokliai

- Pneumatiniai veržlesukiai 1

- Pneumatiniai veržliasukiai 1/2

- Pneumatiniai veržliasukiai 1/4

- Pneumatiniai veržliasukiai 3/4

- Pneumatiniai veržliasukiai 3/8

- Pneumo terkšlės

- Pulverizatoriai

- Pneumo priedai

- Smėliapūtės

- Sraigtiniai oro kompresoriai

- Prekės namams

-

Rankiniai įrankiai

- Atsuktuvai

- Darbastaliai

- Dėžės ir krepšiai

- Dinamometriniai raktai

-

Galvučių ir įrankių komplektai

- Antgalių komplektai

- Galvučių ir įrankių komplektai 1"

- Galvučių ir įrankių komplektai 1/2"

- Galvučių ir įrankių komplektai 1/4"

- Galvučių ir įrankių komplektai 3/4"

- Galvučių ir įrankių komplektai 3/8"

- Galvučių sugadintiems varžtams rinkiniai

- Kombinuoti galvučių ir įrankių rinkiniai 1/4", 3/8", 1/2"

- Smūginių galvučių komplektai

- Galvutės

- Gultai, kėdutės

- Įrankiai įrankių spintelėms

- Įrankiai motociklams, motoroleriams

- Kabių pistoletai

- Kniedikliai

- Kryžminiai raktai

- L ir T tipo šešiakampiai

- L-tipo rankenos galvutėms

- Magnetai / veidrodėliai

- Magnetinės juostelės/laikikliai įrankiams

- Medžio apdirbimo įrankiai

- Padidintos jėgos raktai/reduktoriai ratams

- Peiliai

- Pistoletai montavimo putoms - silikonui

- Prailgintojai

- Raktai

- Raktų komplektai

- Rankiniai pjūklai

- Replės

- Skaičių ir raidžių iškalėjai

- Skylamušiai tarpinėms

- Smeigių, užlūžusių varžtų išsukėjai

- Spaustuvai. Priekalai

- Sriegikliai. Sriegpjovės

- Sriegio atnaujinimo įrankiai, indėklai sriegiams

- Tepalo filtrų atsukėjai

- Terkšlės

- Tvirtinimo elementai terasoms

- Valcavimo įrenginiai

- Vežimėliai įrankiams

- Santechniniai įrankiai

- Saugos priemonės

-

Serviso įranga

- Ašiniai presai

- Detalių plovyklos

- Diagnostinė įranga, įrankiai

- Domkratai

- Hidraulinė įranga

- Hidrauliniai keltuvai / stovai

- Hidrauliniai, mechaniniai spyruoklių suspaudėjai

- Indukciniai kaitintuvai

- Įrankiai duslintuvui

- Įrankiai generatoriaus remontui

- Įrankiai ir įranga kėbulų lyginimui

- Įrankiai purkštukų remontui

- Įrankiai sankabai, greičių dėžei

- Įrankiai stabdžių nuorinimui

- Įrankiai stabdžių remontui

- Įrankiai vožtuvams, cilindrams, stūmokliams

- Kaitinimo ir kibirkštinių žvakių remonto įrankiai

- Keltuvai / stovai motociklams

- Kondicionierių pildymo įranga ir įrankiai remontui

- Nuėmikliai

- Pagalbiniai įrankiai

- Presavimo įrankiai

- Ratų balansavimas / montavimas

- Smūginiai padangų pripūtimo infliatoriai

- Transmisijos domkratai, stendai ir balansyrai varikliams

- Ultragarsiniai valytuvai

- Vamzdžių lenktuvai

- Variklio blokavimo įrankiai

-

Šildymo, vėdinimo įranga

- Dujiniai infraraudonųjų spindulių šildytuvai

- Dujiniai keramikiniai šildytuvai

- Dujiniai tiesioginio degimo šildytuvai

- Dyzeliniai infraraudonųjų spindulių šildytuvai

- Dyzeliniai netiesioginio degimo šildytuvai

- Dyzeliniai tiesioginio degimo šildytuvai

- Elektriniai infraraudonųjų spindulių šildytuvai

- Elektriniai šildytuvai

- Šildytuvų priedai

- Stacionarūs dyzeliniai šildytuvai

- Ventiliatoriai

-

Sodas/Daržas

- Akumuliatoriai vejapjovėms (traktoriukams)

- Aukštapjovės

- Barstytuvai, sijotuvai

- Diskinės malkų pjovimo staklės

- Galąstuvai grandinėms / diskams

- Genėjimo pjūklai

- Grandininiai pjūklai

- Grąžtai žemei

- Gyvatvorių žirklės

- Karučiai

- Kirviai ir kiti miško įrankiai

- Komposto dėžės

- Kultivatoriai ir motoblokai

- Laistymo įranga

- Lapų pūtikai siurbliai

- Lauko daiktadėžės

- Malkų skaldytuvai

- Multifunkciniai įrankiai sodui

- Pakeltos lysvės

- Purkštuvai

- Rankiniai sodo įrankiai

- Šakų smulkintuvai

- Šienapjovės

- Šiltnamiai

- Sniego valytuvai

- Sodo įrangos priedai

- Sodo įrankių nameliai - lauko sandėliukai

- Tepalai sodo technikai

- Trimeriai

- Universalios mašinos

- Vejapjovės

- Vejos aeratoriai / purentuvai

- Vejos traktoriukai

- Žemės kaltai

- ŽEMĖS VOLAI

- Žolės ir krūmų žirklės

-

Statybų įranga

- Benzininiai diskiniai pjūklai

- Betono maišyklės

- Elektrinės plytelių - trinkelių pjovimo staklės

- Giluminiai vibratoriai

- Gipso kartono keltuvai

- Grunto tankinimo įranga

- Metalo formavimo įrenginiai

- Polistirolo pjaustymo peiliai

- Profesionali dažymo įranga

- Rankiniai plytelių ir stiklo pjovimo įrankiai

- Statybinės vaikštynės

-

Suvirinimo įranga

- Apsauga nuo kibirkščių, pastos ir reagentai

- Degikliai bei Pjovikliai su deguonim

- Dujinės žarnos

- Kombinuoti suvirinimo aparatai

- Litavimo instrumentai

- MMA suvirinimo aparatai

- Plazminiai pjovimo aparatai

- Pramoniniai degikliai

- Spoteriai

- Suvirinimo medžiagos

- Suvirinimo pusautomačiai

- Suvirinimo reikmenys ir priedai

- Suvirinimo skydeliai

- TIG suvirinimo aparatai (AC/DC)

- TIG/MMA Suvirinimo aparatai

- Tepimo įrankiai. Pompos

- Tepimo priemonės

- Transportavimo įranga

- Ūkio prekės

-

Valymo įranga

- Aukšto slėgio plovyklos

- Gariniai įrengimai

- Grindų poliravimo įrenginiai

- Langų plovimo įrengimai

-

Siurbliai

- Akumuliatoriniai dulkių siurbliai

- Buitiniai dulkių siurbliai su vandens filtru

- Buitiniai plaunantys dulkiu siurbliai

- Buitiniai sauso siurbimo siurbliai

- Buitiniai sauso-šlapio siurbimo siurbliai

- Buitiniai siurbliai - robotai

- Dulkių siurblių priedai

- Profesionalūs plaunantys dulkiu siurbliai

- Profesionalūs sauso siurbimo dulkių siurbliai

- Profesionalūs sauso-šlapio siurbimo siurbliai

- Siurbliai pelenams

- Šlavimo įrenginiai

- Valymo cheminės priemonės

- Vandens siurbliai

- Vidaus degimo varikliai

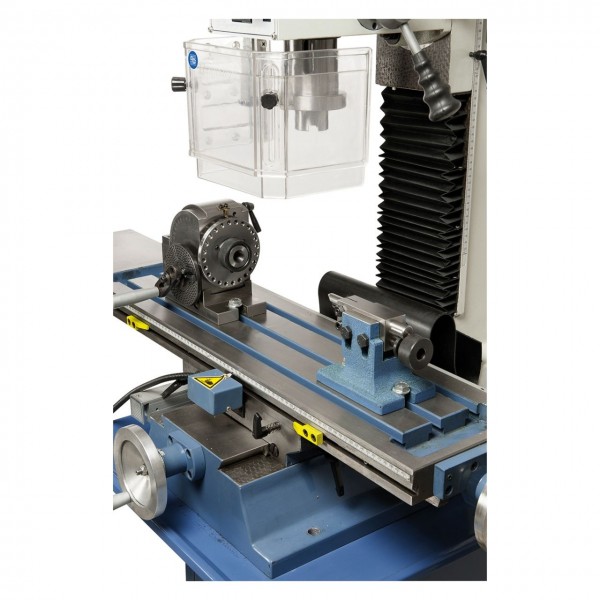

Gręžimo - frezavimo staklės Bernardo BF 30 N Super

Gręžimo - frezavimo staklės Bernardo BF 30 N Super

Many possible applications, such as groove milling, face milling, reboring etc.

Digital speed and spindle stroke indicator included as standard equipment

2-step gear unit for optimal power transmission

Serially equipped with left and right turning, ideal for thread cutting

Direct current motor for ideal torque at lower speed

Dovetail guiding for the x-, y- and z-axis, adjustable via gibs

High-quality bearings guarantees high spindle concentricity (≤0.015 mm)

Mill head tiltable to both sides for angular boring, milling of bevels etc.

Large, surface treated cross table

Handle for spindle adjustment, handwheel for fine feed

Technical specifications

Drilling capacity in steel 30 mm

Face mill capacity max. 75 mm

End mill capacity max. 25 mm

Distance spindle to column 180 mm

Distance spindle to table 115 - 465 mm

Spindle stroke 70 mm

Spindle speed, stepless 50 - 1100 / 150 - 3000 rpm

Spindle taper MT 3

Table size 840 x 210 mm

Travel (x / y) 455 / 195 mm

Mill head tiltable -90° to +90°

Height adjustment of mill head 350 mm

T-slot size 14 mm

Motor power output S1 100% 1,1 kW / 230 V

Motor power input S6 40% 1,6 kW / 230 V

Machine dimension (W x D x H)* 1350 x 710 x 1200 mm

Weight approx. 222 kg

Standard accessories

x-axis power feed AL 350 D

Keyless drill chuck 1 - 16 mm / B 16

Drill chuck arbor MT 3 / B 16

Drawbar M 12

Digital speed indicator

Digital spindle stroke indicator

EMC filter according to CE standard

Height adjustable protective cover

Tools